Steel wire for steel-cored aluminum stranded wire

Refer to the standard ASTM B498 ASTM A 475; Production of BS 183, etc. By surface galvanizing to enhance the corrosion resistance of the steel wire, the zinc layers we can produce are of Class A grade. Class B level and Class C level.

The zinc coating surface of Class A grade is smooth, but its anti-corrosion ability is weaker than that of Class B and Class C. It is used in general-purpose places.

Grade B and Grade C have very high corrosion resistance and can be used in damp and harsh environments such as coastal areas.

In addition, our company can also produce zinc-aluminum alloy coated products for customers to choose from

Monofilament diameter range: 1.57 -6.00 mm

Zinc coating range

Wire diameter | Minimum zinc layer (g/m2) | ||

| Standard zinc layer | thick zinc layer | Ultra thick zinc layer |

1.6 mm -1.90mm | 210 | 420 | 630 |

1.90mm - 2.30mm | 220 | 440 | 660 |

2.30mm - 2.70mm | 230 | 460 | 690 |

2.70mm - 3.10mm | 240 | 480 | 720 |

3.10mm - 3.50mm | 260 | 520 | 780 |

3.50mm - 3.90mm | 270 | 540 | |

Tensile strength (Mpa)

Tensile strength is used to specify the breaking force of steel wire and can be classified into three levels

Wire diameter | Stress at 1% extension(Mpa) | ||

A | B | C | |

1.6 mm - 2.30mm | 1310 | 1240 | 1170 |

2.30mm- 3.05mm | 1280 | 1210 | 1140 |

3.05mm - 3.60mm | 1240 | 1170 | 1100 |

3.60mm - 4.80mm | 1170 | 1100 | 1070 |

Wire diameter | Tensile strength (Mpa) | ||

A | B | C | |

1.6 mm - 2.30mm | 1450 | 1380 | 1310 |

2.30mm- 3.05mm | 1410 | 1340 | 1280 |

3.05mm - 3.60mm | 1410 | 1340 | 1280 |

3.60mm - 4.80mm | 1380 | 1280 | 1240 |

Wire diameter | Extension (%) | ||

Class A | Class B | Class C | |

1.6 mm - 2.30mm | 3 | 3 | 3 |

2.30mm- 3.05mm | 3.5 | 3 | 3 |

3.05mm - 3.60mm | 4 | 3 | 3 |

3.60mm - 4.80mm | 4 | 4 | 4 |

Chemical composition of steel

Our company offers a variety of steel base materials for selection, and at the same time, lead quenching treatment can be used to achieve different strengths. The following table shows the chemical composition of steel

Strength grade | % Carbon | % Phosphorus | % Manganese | % Silicon | %Sulfur |

Ordinary | 0.45~0.50 | 0.032 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

High | 0.59~0.63 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Extra high | 0.65~0.83 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Quality Control

Our company has passed the ISO 9001 and ISO/TS 16949 quality management system certifications. Both raw materials and semi-finished products will be tested and recorded in the files. Traceability records can trace every link from raw materials to finished products.

Professional Team

We are committed to providing the best service to our customers.

★Our sales team has professional product knowledge and rich application experience. They are optimistic and enthusiastic and provide you with the most attentive service.

★No matter what questions you have about our products after receiving the goods, our after-sales service team will patiently answer for you and solve the problem for you in time.

Quality mold source supplier

Many years of industry experience, with standardized production workshop more than 1100 square meters. Has a strong refractory brick mold design, production capacity, with strict quality control system and a number of high-quality staff.

Advanced equipment professional team

More than 30 sets of advanced production machinery and equipment: 9 sets of machining centers, 5 sets of numerical control lathes, 8 sets of planers, 3 sets of section milling machines, 2 sets of vertical milling machines, 1 set of grinding machines, 2 sets of well-type electric furnaces and other auxiliary equipment.

Quality for the first personality customization

There is no omission in the whole process of tracking and inspection to ensure that the products meet the quality requirements. The professional production and manufacturing team will tailor the refractory materials according to your different needs to meet the different needs of different customers.

All-round solution to after-sales problems

Customer service is online 24 hours a day, answering questions for customers at all times, providing considerate services, establishing customer documents with our cooperating customers, paying regular return visits to product usage, and serving every customer attentively.

Steel wire for steel cored aluminum stranded wire

Key words:

Steel wire for steel cored aluminum stranded wire

Classification:

Recommend products

Products in strict accordance with YB/T024-2021 and GB/T3082-2008 standard implementation of production, product quality and good reputation.

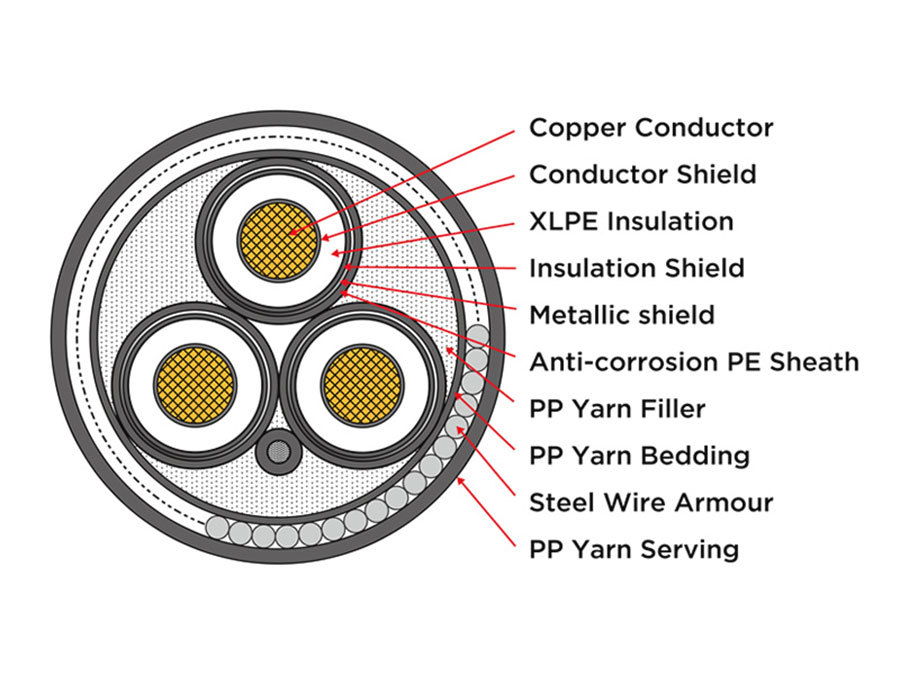

Specialized in the Production of Armored Cable Steel Strip and Steel Wire

E-mail: sherry@zhongbosteel.com

Address: Qiliyan, Lihe Town, xinzheng city, Henan Province

Copyright©2025 Xinzheng Zhongbo Steel Products Co., Ltd.

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSXZE-SAD

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page