Water cooling tank

Production Line

This production line is at the forefront of China's hot-dip galvanized steel wire manufacturing technology, delivering high efficiency, superior quality, and eco - friendliness. Here's a concise breakdown of the production process:

1. Non-stop H-shaped Wheel Pay-off: The process kicks off with a non-stop H-shaped wheel pay-off system, enabling continuous wire feeding without halting the line.

Spool Pay-off

2. Annealing: The wire then undergoes annealing in a counter - flow gas - fired furnace, ensuring uniform temperature and optimal quality.

Gas-fired open-flame heat treatment furnace

3. Cooling: Post - annealing, the wire is cooled via a combination of air and water cooling to stabilize its strength.

4. Water Cooling Trough

Rapid cooling enhances mechanical consistency.

5. Smoke - free Acid Pickling: The wire is cleaned in a smoke - free acid pickling tank to remove surface oxides, ensuring high - quality galvanizing while preventing acid mist

pollution.

6. Acid Mist Purification

Dual-tower scrubber ensures full environmental compliance.

7. Water Washing: Residual acid is removed in a water washing tank.

Water washing tank

8. Fluxing: The cleaned wire is coated with flux from a heated and circulated flux solution in the fluxing tank, preparing it for galvanizing.

9. Drying: Electrically heated drying ovens remove moisture from the wire, preventing defects during galvanizing.

Drying furnace

10. Hot - dip Galvanizing: In a ceramic zinc pot, molten zinc uniformly coats the wire, with precise temperature control ensuring coating quality.

Internally heated ceramic zinc pot

11. Vertical Support Frame

Vibration-dampening structure ensures smooth wire travel.

12. Ceramic Guide Rollers

High-wear components withstand extreme temperatures.

Ceramic pressure guide roller

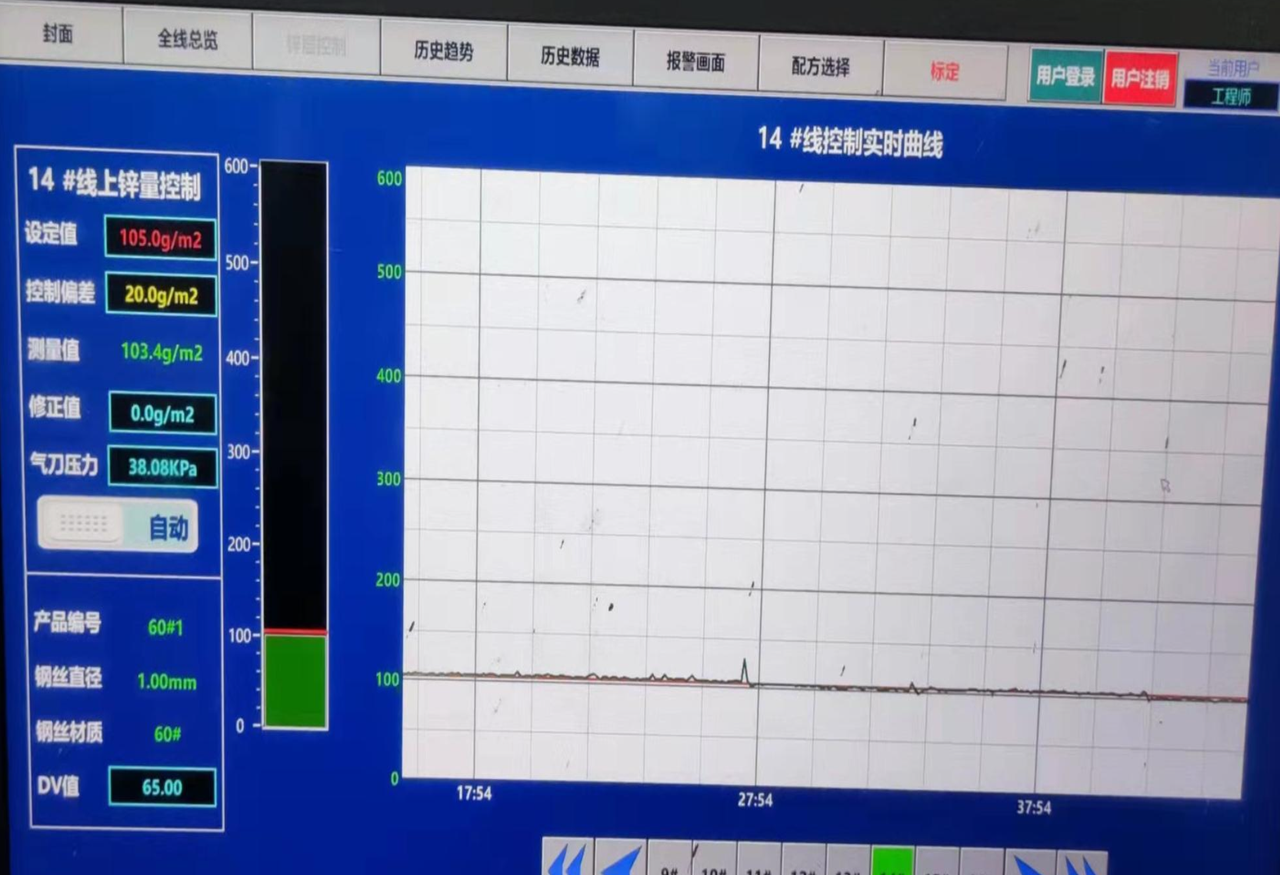

13. Nitrogen Wiping: A nitrogen wiping system precisely controls the zinc coating's thickness for consistent quality.

Nitrogen wiping and control system

14. Post-Coating Cooling: The galvanized wire is quickly cooled using water and air cooling methods to enhance coating adhesion and surface finish.

15. Inverted Take-up: An inverted take-up machine with a pneumatic accumulator arm and inverter ensures stable and accurate wire winding.

Inverted take-up machine

16. Packaging: A semi-automatic baler efficiently packages the finished wire, reducing labour requirements.

Baler

Specialized in the Production of Armored Cable Steel Strip and Steel Wire

E-mail: sherry@zhongbosteel.com

Address: Qiliyan, Lihe Town, xinzheng city, Henan Province

Copyright©2025 Xinzheng Zhongbo Steel Products Co., Ltd.

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSXZE-SAD

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page